Can you use aluminum wire for your generator? Despite some negative press, aluminum wire is safe for use in generators.

Aluminum wire has a bad reputation as a fire starter. The public mind associates the wiring with several house fires caused by aluminum wires between 1960 and 1970. Aluminum, however, is safe for use with electricity, and its lightweight malleability makes it ideal for smaller projects.

We’ll look into the following main topics about the aluminum wire in generators:

- the best wire for your generator

- the benefits of aluminum wiring versus copper wiring

- the dangers of aluminum wiring

- the importance of amps, voltage, and current

- suggestions for picking the best-sized wire for your generator project

Keep reading so you’re accurately informed about the use of aluminum in generators.

What Wire Do You Use for a Generator?

The correct wire for size and type depends on the variety of the generator. Several considerations factor into determining the right wire for your generator. These include:

- Voltage wires should be rated for the systems voltage

- Current-wired need to be durable enough to transmit the current

- Circuit Breaker-the rating of the wire needs to match the rating of the circuit breaker

- Length of the Wire-longer wires causes voltage drops. Make sure the voltage drops no more than three percent.

Determine the appropriate wire by following these steps:

Look at the Nameplate

Before determining which wire you need, you must attain certain specifications about your generator and circuit breaker. A generator’s nameplate includes the salient information you’ll need to select your wire.

The generator lists the voltage in volts and power in watts. Voltage ranges from 120 and 240 volts, and the power can be between 1000 to 10,000 watts.

Check the Amp Rating

Match your wire’s current rating to your circuit breaker’s current rating. Due to elevated temperatures, current ratings measure how much current your breaker carries without any variation in voltage or frequency.

Most circuit breakers vary between 15A and 50A, with the corresponding wires ranging from 14 AWG to 6 AWG.

Calculate the Load Current

The full load current is the amount of current needed for proper function. Figuring out how much load current your wires need to transmit requires some math.

The formula for generators with one circuit breaker is power in watts divided by voltage. Use the formula: connected loads in watts divided by load voltage for generators with branch circuit breakers.

Check the Voltage Drop

The wires to your generator shouldn’t allow for a voltage drop of over three percent. The longer the wire, the more significant the reduction. You need to know the resistance of your wires to ascertain the voltage drop. Once you have determined the resistance of your wire, multiply that number by the current, or simply use this voltage drop calculator.

Can Aluminum Wire Be Used for Electricity?

Aluminum wire can and is used to conduct electricity. Aluminum’s conductivity to weight ratio is better than copper’s. This ratio means that aluminum wire can transmit 61 percent as much electricity as copper wiring while weighing considerably less. Aluminum’s lightness makes it ideal for specific electric wiring jobs, such as:

- Power grids

- Overhead power lines

- Airplane wiring

- Local electric provider lines

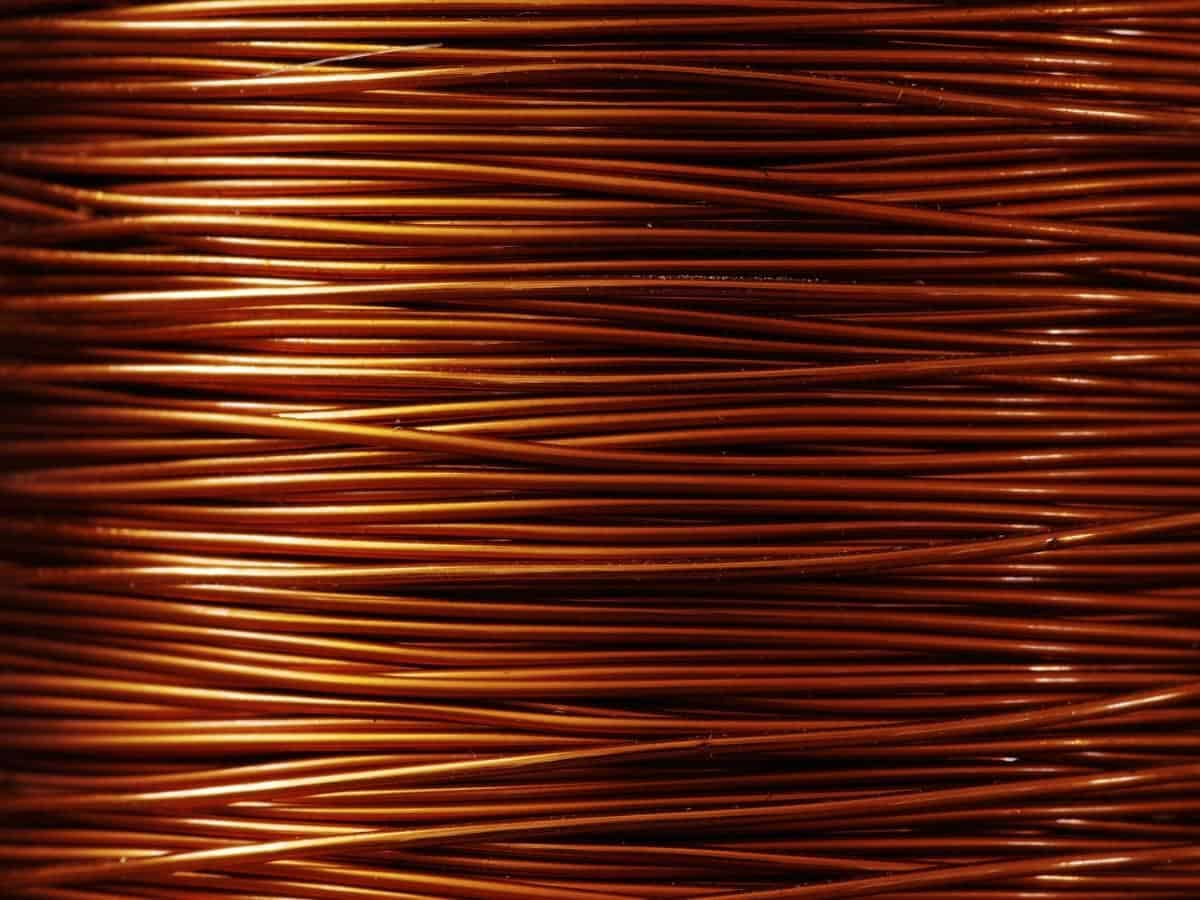

Is It OK To Use Aluminum Wire Instead of Copper?

Aluminum wire and copper wire have different strengths. You can safely use both. However, copper is generally considered the superior option for in-home wiring. Copper is more stable and usually safer.

Aluminum wire, however, is considerably cheaper than copper wire, usually costing about half the price of copper. It’s best to use aluminum wire for low amp jobs, such as:

- HVAC Circuits

- Dryer Circuits

- Feeder cables

- Service Entrance conductors

Copper wire works better for higher amp jobs. Aluminum wire only safely transmits 61 percent of the current copper wire can carry.

There are benefits and disadvantages to using aluminum wire versus copper. Starting with the pros, these include:

- Aluminum wire costs markedly less than copper wire.

- Aluminum wire is flexible and works well for usage in small spaces.

The negative aspects of aluminum wire include:

- Aluminum wire is weaker and more breakable than copper wire.

- Aluminum wire has a higher thermal expansion coefficient

- Aluminum wire rusts and corrodes quickly. The rust impedes electric flow and can cause over-heating

What Is Wrong With Aluminum Wiring?

Modern aluminum wire is mainly safe. We perceive aluminum wire as dangerous because of the variety used between 1960 and 1970—solid conductor aluminum wire. These wires were single strands versus modern wires, which are multi-strand.

Luckily, the U.S. Consumer Product Safety Commission offers three solutions to old and potentially dangerous aluminum wiring. These are:

- The Copalum Method-the technique is achieved by fusing a copper pigtail to the aluminum wire, then terminating the copper on the device.

- Swap the switches and receptacle devices with ones compatible with aluminum wiring.

- Bind the aluminum wires to a copper pigtail using a lugnut or cog.

A trained electrician should only ever complete these fixes.

Aluminum wiring is more malleable than copper, making it more breakable and weaker. However, the more significant problem with aluminum wiring is one of expansion. When the wires get hot, they expand; when they cool, they contract again. This process loosens the wires, increasing the chances of sparking.

When aluminum wire oxidizes, it creates aluminum oxide, slowly destroying the wire’s connection.

When Can I Use Aluminum Wire?

Aluminum wire is highly conductive, so is good for use in electrical wiring. Aluminum wiring is lightweight and malleable, which makes it a good option for long-distance wiring jobs. Just be sure your devices are safety rated for aluminum.

Can Aluminum Wire Be Used for Branch Circuits?

Aluminum wire has been used for branch circuits in the past and still exists in many homes today. Now, however, aluminum is banned in branch circuits, owing to the volatility of the wires.

Generator Wire Size Chart

The chart below will help you determine the correct sized wire for your generator. First, however, you need to do a little math. Figure out your voltage drop index with the formula: Amps(watts divided by volts) times feet (wires distance) divided by the acceptable percentage of voltage drop-two to five percent. Once you determine that number, use the charts below to pick your wire:

Copper Wire Size Chart

| Size: | Voltage Drop Index | Ampacity |

| 0000 | 99 | 260 |

| 000 | 78 | 225 |

| 00 | 62 | 195 |

| 0 | 49 | 170 |

| 2 | 31 | 130 |

| 4 | 20 | 95 |

| 6 | 12 | 75 |

| 8 | 8 | 55 |

| 10 | 5 | 30 |

| 12 | 3 | 20 |

| 14 | 2 | 15 |

Aluminum Wire Chart

| Size: | Voltage Drop Index | Ampacity |

| 0000 | 62 | 205 |

| 000 | 49 | 175 |

| 00 | 39 | 150 |

| 0 | 31 | 135 |

| 2 | 20 | 100 |

| 4 | 12 | 75 |

Generator Wire FAQs

Choosing the correct wire is a challenging but essential process. Here are a few FAQs:

What size wire do I need for a 20 amp generator?

The wire you choose must support the circuit breaker connected to the generator. A twenty amp generator requires a twelve-gauge wire.

What size wire can handle 30 amps?

The best-sized wire for a 30 amp breaker is a ten gauge. You can use a smaller gauge if necessary, but a larger gauge is a fire hazard.

What size wire do I need for a 30 amp generator?

A 30 amp generator requires a ten-gauge or large wire.

Sources: